After still more tests, I came to the following conclusions:

1. The "weld line" like boundary issues were caused by two separate problems:

a. The "weld-line" near the base is caused by a too low poly mesh for any renderer to faithfully construct. This

region is where a curved surface abruptly changes direction to meet another curved surface. Unless the

mesh has high enough resolution to record enough normals to faithfully reconstruct this boundary, it can

only go with the limited information the mesh actually possesses. Apparently, Octane exaggerates the

problem as of beta 2.57/2.58. The only solution is to use a much higher poly count.

b. All the other "weld'lines" were caused by a too low poly mesh for Octane for this type of object (even

though it had 273,880 polys). Apparently, and on a very smooth curvature where there are no abrupt

direction changes, if a mesh has a fairly regular polygon pattern that must meet up with another fairly

regular polygon pattern of different form, then a boundary between the two areas must be constructed that

patches the two areas together when the mesh is built (See closeup mesh image in earlier post). This is not

tolerated well in MaxwellRender or Octane, but it is far worse in Octane at this beta stage. The only solution

is to use a much higher poly count.

2. The OctaneExporter for Cinema4D (R12) is not part of the problem. The problem is in C4D itself, in part...After

exporting OBJ's via their native exporter, their Okino Wavefront exporter, and OctaneExporter, all had the

same identical problems, namely zigzagging and "weld-lines" when brought into Octane. So, I conclude that

C4D imports meshes and does something to the normals as some internal operation that cannot be adjusted or

turned off. Nothing in Preferences is available to counteract the problem. I validate this by the test I did

where I exported a higher poly OBJ file out of Maxwell (after Recalc Normals was clicked and smoothing angle

set to 89.5 deg) and directly imported it into Octane without passing through C4D. It rendered fine with hardly

any artifacts issues. I then took the OBJ export that was made in C4D (the same file that caused problems in

Octane), sent it back through Maxwell and re-exported it as another OBJ. This one also rendered fine in

Octane without much issue. Regardless of the path that the OBJ took from modeler to Octane, C4D corrupted

the quality of the OBJ in such a way that the original mesh quality could not be completely restored via

Maxwell's "Recalc Normals" function.

3. Exporting the OBJ mesh directly from my solid modeler (Creo) into Octane did not cause ANY issues that would

require post work in Photoshop, provided the mesh had a high enough poly count. Unfortunately, you cannot

export a Creo OBJ with more than four materials or the extra materials will simply be ignored and the resulting

surfaces ganged up randomly with the prior four....So this is not an option for Octane as of Beta 2.57/2.58. But

at least Creo respected the quality of the data it exported in the OBJ to the fullest degree.

4. Exporting the OBJ mesh directly from MaxwellRender into Octane did not cause any significant issues. With

what issues were apparent, lowering the Smoothing Angle from 89.5deg to something like 30deg helped to a

certain extent. But again, and unfortunately, you cannot export a Maxwell scene as one single OBJ file...All the

objects in the scene get exported to individual files, so this is not an option for Octane either, as of Beta

2.57/2.58.

5. MaxwellRender and Octane each have their own problems when interpreting OBJ files. However, when a

mesh is being uncooperative, Maxwell's "Recalc Normals" function can be a life-saver even though it does not

always remove all problems regarding normals. That having been said, I have never had a "perfect" render

out-of-the-box...Every render requires some post work in Photoshop to one degree or another, even if it is

minor.

6. The Wavefront OBJ format is probably a very good format, but unfortunately, it seems that each software

manufacturer takes liberty with the specification by doing things that divert from it in dangerous ways. For

instance, some exporters only export the OBJ file, not it's partner, MTL material file. This is not desirable in

that some applications may require the MTL file in order to properly load the OBJ file, and may hang or crash as

a result. Any well-written software should be able to avoid such a catastrophe by checking for the existence of

the MTL file first and should be able to generate its own default MTL if need be, when the MTL file does not

exist. The problem is that this ASSUMES that such software is written properly to detect such a problem, and

clearly, even if the software was NOT written to detect the problem, the OBJ file should always come with its

MTL file anyway...Even if it is nothing more than a default file with default materials. Some programmers

assume that just because their proprietary materials system cannot be exported to the OBJ format that they

should just ignore the MTL. This is sloppy programming practice since the OBJ format specifically includes the

MTL partner file.

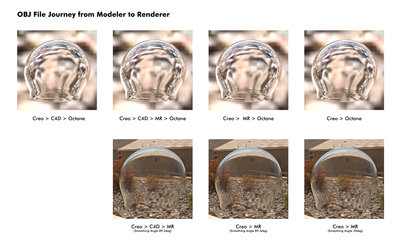

This image shows my latest tests:

Another issue appears to be that each software vendor may be taking liberty with the accuracy of the data contained in the OBJ file. This is the only reason I can come up with to explain how one program can corrupt the quality of an OBJ as it passes through it from initial import to export. Or maybe they feel they should do something to the data because they feel it is important to fit the needs of their own software. Whatever the reason, the result is an exported OBJ that pulls away from the expected standard specification, and that causes nothing but grief for people who need to incorporate that data in their own programs. Interoperability is compromised because of lazy programming practices. The correct course to take when interoperability is concerned is to take into account the accuracy of the data that other software may require and if internally that accuracy is not used, then keep a preserved copy of the original data in case the file is to be exported, and to always do calculations at a high level of accuracy when it affects a possible export.

Where does this leave me and anyone else with a similar problem? Clearly, the perfect solution would be the ability for me to export out directly from Creo to Octane. Unfortunately...due to sloppy programming...Creo's exporter only allows a maximum of four materials!! Go figure. Where did the magic number "4" come from anyway?! Was it part of the OBJ specification? NOOOOOOOOO!

So my only other option is to use an intermediary step to combine my parts into a single OBJ file...A step which does not easily exist...Unless....Just unless, Octane soon (pretty please, VERY SOON) allows the rendering of multiple OBJ files. I will be in Heaven on that day. And a Recalc Normals button would sure be a great safety net when needed.